Products

Best Famous Non Metal Precision Parts Exporters – Sheet Metal Stamping Produce Parts – Excellent Intelligent Equipment

Best Famous Non Metal Precision Parts Exporters – Sheet Metal Stamping Produce Parts – Excellent Intelligent Equipment Detail:

Products Description

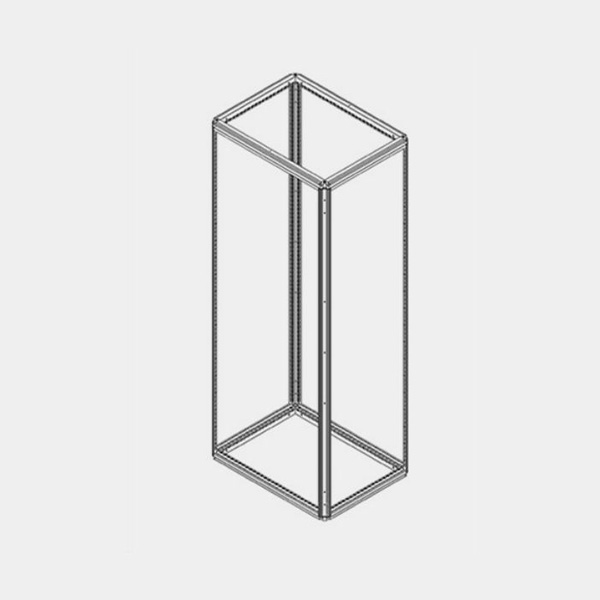

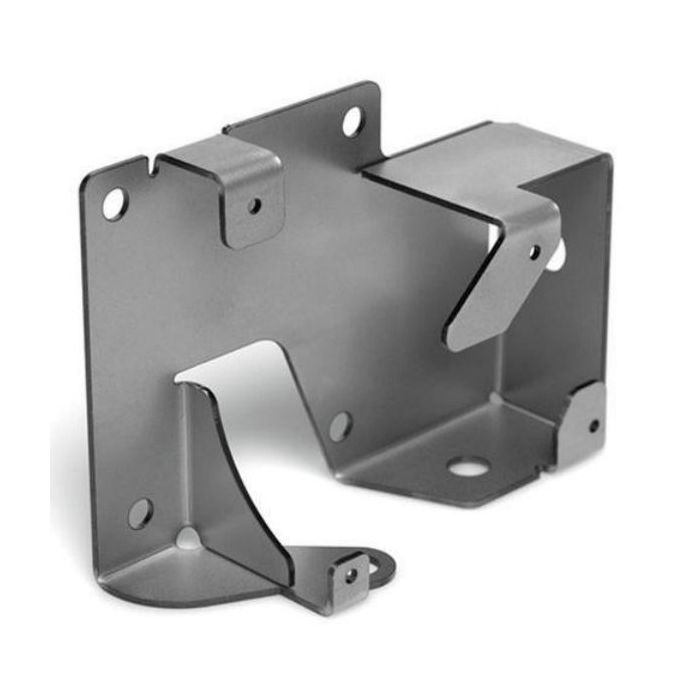

Generally speaking , Sheet metal stamping process includes plate cutting into due form,blanking ,punching,bending ,flanging ,embossing ,coining and forming, etc. Depending on required procedures,one or multiple die stations might be needed for single or multiple operation to finish work pieces.Our business stands out with advantages of die set R&D facilities.In addition to sheet metal stamping operations.We also help customers design and manufacture metal stamping die .

Key Features

Sheet metal stampings generally refer to the plasticity of metals. For thin metal plates with a certain thickness, a single stamping part is manufactured through processes such as cutting, stamping, and bending, and then assembled through welding, riveting, etc. to complete the assembly. Its characteristic is that the thickness of the same part is the same.

In the design process of sheet metal stamping parts, in addition to the need to express the shape and size of the part with engineering drawings, it is also necessary to use the unfolded drawing of the sheet metal to represent the sheet metal outline shape and size before the production and processing of the sheet metal part. It is used to guide the blanking, layout and production of sheet metal stamping parts. According to the requirements of the three-dimensional shape of the part, the process of drawing the contour of the flattened shape is the unfolding pattern of the sheet metal part. Mastering the correct and effective method of sheet metal parts exhibition and sampling can not only ensure the accuracy of sheet metal stamping parts, but also improve processing efficiency and save costs.

Because sheet metal stamping produce parts have the characteristics of light weight, high strength, electrical conductivity, low cost, and good mass production performance, they are currently widely used in petrochemical, metallurgy, electronic appliances, communications, automotive industry, medical equipment and other fields. For example, in daily products such as computer cases and mobile phones, sheet metal stamping is an indispensable processing technology. With the increasing application of sheet metal, the design of sheet metal stamping parts has become a very important part of the product development process. Mechanical engineers must be proficient in the design skills of sheet metal stamping parts, so that the designed sheet metal parts can not only meet the requirements of product function and appearance, but also meet the requirements of convenient production and processing and cost-effectiveness.

In the stamping process, highly specialized computer-aided drawing and manufacturing procedures are used to transform sheet metal into complex parts. Sheet metal stamping can quickly and efficiently produce high-quality, flexible and heavy-duty parts. The results are very precise, and they are generally more reliable and consistent than manual processing. The following industries use components created by sheet metal stamping: automotive, renewable energy, medical, industrial, aerospace, hardware, home improvement.

Product detail pictures:

Related Product Guide:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Best Famous Non Metal Precision Parts Exporters – Sheet Metal Stamping Produce Parts – Excellent Intelligent Equipment , The product will supply to all over the world, such as: Malawi, Pakistan, Japan, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.