Products

China High Quality Aircraft Sheet Metal Fabrication Manufacturer – Sheet Metal Stamping Produce Parts – Excellent Intelligent Equipment

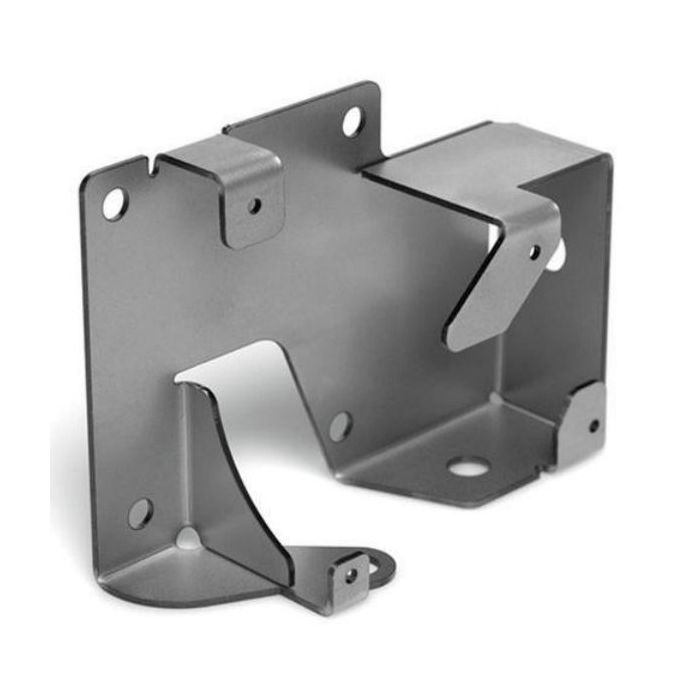

China High Quality Aircraft Sheet Metal Fabrication Manufacturer – Sheet Metal Stamping Produce Parts – Excellent Intelligent Equipment Detail:

Products Description

Generally speaking , Sheet metal stamping process includes plate cutting into due form,blanking ,punching,bending ,flanging ,embossing ,coining and forming, etc. Depending on required procedures,one or multiple die stations might be needed for single or multiple operation to finish work pieces.Our business stands out with advantages of die set R&D facilities.In addition to sheet metal stamping operations.We also help customers design and manufacture metal stamping die .

Key Features

Sheet metal stampings generally refer to the plasticity of metals. For thin metal plates with a certain thickness, a single stamping part is manufactured through processes such as cutting, stamping, and bending, and then assembled through welding, riveting, etc. to complete the assembly. Its characteristic is that the thickness of the same part is the same.

In the design process of sheet metal stamping parts, in addition to the need to express the shape and size of the part with engineering drawings, it is also necessary to use the unfolded drawing of the sheet metal to represent the sheet metal outline shape and size before the production and processing of the sheet metal part. It is used to guide the blanking, layout and production of sheet metal stamping parts. According to the requirements of the three-dimensional shape of the part, the process of drawing the contour of the flattened shape is the unfolding pattern of the sheet metal part. Mastering the correct and effective method of sheet metal parts exhibition and sampling can not only ensure the accuracy of sheet metal stamping parts, but also improve processing efficiency and save costs.

Because sheet metal stamping produce parts have the characteristics of light weight, high strength, electrical conductivity, low cost, and good mass production performance, they are currently widely used in petrochemical, metallurgy, electronic appliances, communications, automotive industry, medical equipment and other fields. For example, in daily products such as computer cases and mobile phones, sheet metal stamping is an indispensable processing technology. With the increasing application of sheet metal, the design of sheet metal stamping parts has become a very important part of the product development process. Mechanical engineers must be proficient in the design skills of sheet metal stamping parts, so that the designed sheet metal parts can not only meet the requirements of product function and appearance, but also meet the requirements of convenient production and processing and cost-effectiveness.

In the stamping process, highly specialized computer-aided drawing and manufacturing procedures are used to transform sheet metal into complex parts. Sheet metal stamping can quickly and efficiently produce high-quality, flexible and heavy-duty parts. The results are very precise, and they are generally more reliable and consistent than manual processing. The following industries use components created by sheet metal stamping: automotive, renewable energy, medical, industrial, aerospace, hardware, home improvement.

Product detail pictures:

Related Product Guide:

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction for China High Quality Aircraft Sheet Metal Fabrication Manufacturer – Sheet Metal Stamping Produce Parts – Excellent Intelligent Equipment , The product will supply to all over the world, such as: Southampton, Indonesia, Estonia, Nowadays our products sell all over the domestic and abroad thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!