Products

China High Quality Stamping Process Sheet Metal Suppliers – Sheet Metal Fabrication Turret Punching – Excellent Intelligent Equipment

China High Quality Stamping Process Sheet Metal Suppliers – Sheet Metal Fabrication Turret Punching – Excellent Intelligent Equipment Detail:

Products Description

Turret punches and laser cutters process sheet metal into parts by cutting the material. Learn more about each process:

Turret punching: During the turret punching process, the operator places a sheet of metal between a punch and a die. The punch presses into the material, pushing excess metal into the die. Computer numerical control (CNC) turret punching uses computer programming to follow a design’s direction. This coding allows the punch to perform an automated cutting process.

Laser cutting: Laser cutters use a focused beam and gas to vaporize sheet metal. The beam cuts through the metal, then a stream of gas blows through the cut area to form the desired cutout. Coated mirrors guide and focus the laser beam while shielding it from the operator’s eyes. A laser cutter can also use CNC technology to automate the vaporization process.

Key Features

Compared to a laser cutter, a turret punch has a more economical price and can perform more tasks. These factors combined lead to higher cost competitiveness for turret punching than laser cutting. When a business chooses a fabrication company that uses turret punching, the savings pass on to their

On average, a turret punch makes fewer hits per minute than a laser cutter, but additional factors improve its efficiency. An advanced laser cutter can perform 10,000 hits per minute compared to turret punching’s 1,000. However, a turret punch’s versatile capabilities and reduced lead times can make up for the fewer hits per minute.project costs.

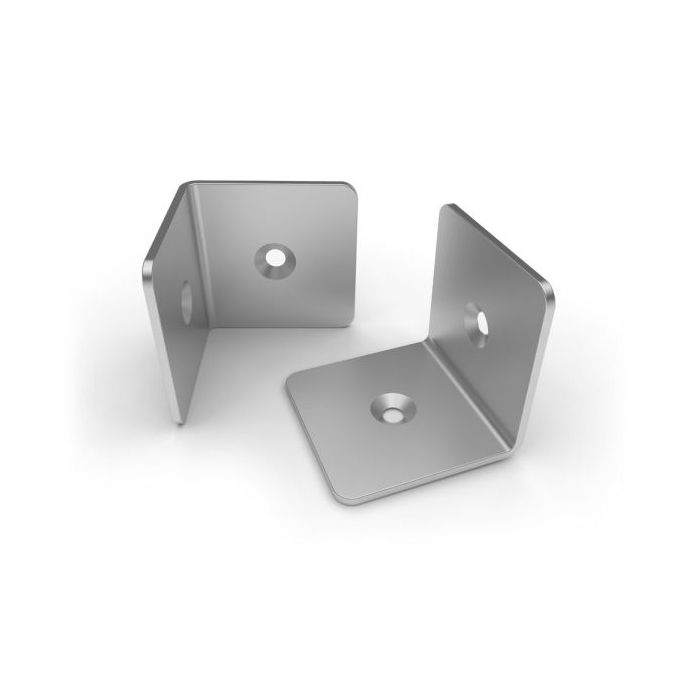

Turret punching is the best option for when you need a repeated design but want to retain precision and accuracy. A turret punch uses a group of tools to punch through the sheet metal and they are commonly used to create round, square or rectangular holes of different diameters, dimples or louvres.

Though they cannot create complex designs like laser cutting, using a turret punch can reduce the time taken to produce medium and long runs of the same component. This makes it a cost-effective option for customers who require large numbers of a particular sheet metal components with perforations or other simple cut-outs.

Product detail pictures:

Related Product Guide:

Every single member from our large efficiency revenue team values customers' wants and company communication for China High Quality Stamping Process Sheet Metal Suppliers – Sheet Metal Fabrication Turret Punching – Excellent Intelligent Equipment , The product will supply to all over the world, such as: San Diego, Nigeria, Zurich, We've a skilled sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique merchandise.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!