Products

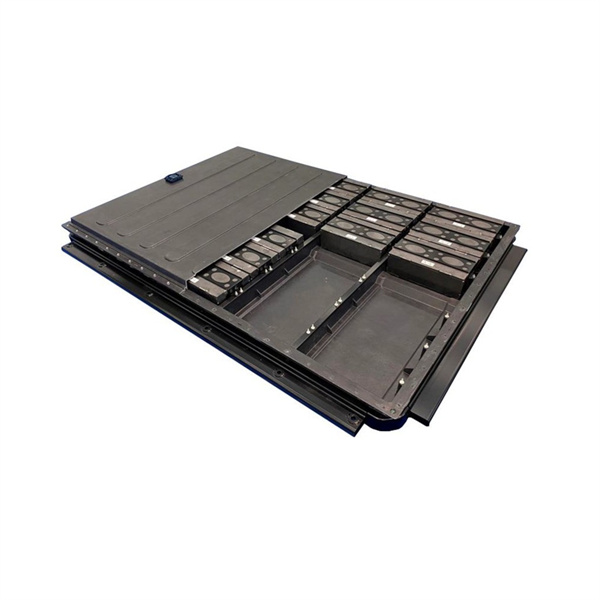

Fabrication Sheet Metal Forming Stamping Parts

Fabrication sheet metal forming stamping part refers to the manufacturing process starting from sheet metal coil placed into the stamping machine. Once the feeds reach the forming station, the die set installed inside the stamping machine punches the material into desired shapes. After the sheet metal is made into a net shape by the die set, the manufacture could be completed in stages. The die set is designed in accordance with the shape of the finished products. The stamping process can be done through various methods such as bending, punching, flanging, embossing, extrusion, extension and shearing. It could involve single-stage motion or multiple methods applied in stages on sheet metal or non-metallic material.

Key Features

The choice of the type of stamping presses and manufacturing process depends on the complexity of the finished products with other factors including the material, thickness, measurements and quantities taken into consideration. Generally speaking, micro or miniature complex precision metal stamping parts in large quantities such as terminals and connectors widely used in the electronics industry are usually manufactured with high-speed presses and progressive dies. Whereas large progressive stamping parts in smaller quantities are usually manufactured with heavy-duty presses of higher tonnage capabilities and single-stage dies. We offer flexible solutions for various business needs. In the case of even smaller order quantities due to unsteady annual demands, we offer manufacturing options of NCT punch processing (Numerical Control Turret Punch Press), which would help our customers avoid pricey die set design and development costs in progressive precision stamping products.

The choice of the type of fabrication sheet metal forming stamping presses and manufacturing process depends on the complexity of the finished products with other factors including the material, thickness, measurements and quantities taken into consideration. Generally speaking, micro or miniature fabrication sheet metal forming stamping parts in large quantities such as terminals and connectors widely used in the electronics industry are usually manufactured with high-speed presses and progressive dies. Whereas large progressive stamping parts in smaller quantities are usually manufactured with heavy-duty presses of higher tonnage capabilities and single-stage dies. We offer flexible solutions for various business needs. In the case of even smaller order quantities due to unsteady annual demands, we offer manufacturing options of NCT punch processing (Numerical Control Turret Punch Press), which would help our customers avoid pricey die set design and development costs in progressive fabrication sheet metal forming stamping products.