Products

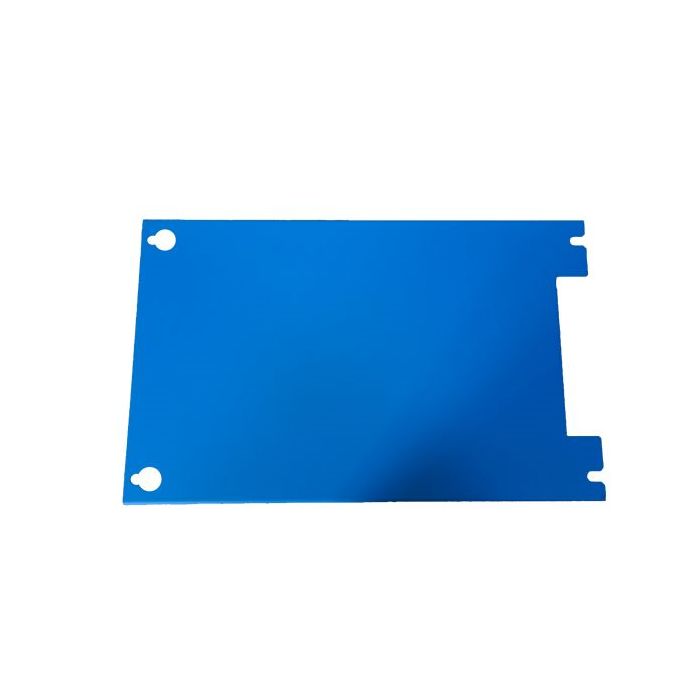

Sheet Metal Box Parts Fabrication

Sheet metal box fabrication is a complex process used in forming flat sheet stainless steel or carbon steel into the various shape of enclosures.Sheet metal boxes are two-part enclosures produced by cutting , forming , and assembling sheet metal . Sheet metal is a durable material.It can be cut, bent ,or stretched to any design and shape of the enclosure .

Numerous types of sheet metal boxes are available suitable for various fabrication processes such as steel, aluminum,magnesium,copper,and bronze.Sheet Metal box part is used for different purpose such as control panels, distribution boxes, electronics enclosures boxes,etc.

Key Features

We uses several types of sheet metals box fabrication suitable for various fabrication processes. Here are some of the durable sheet metals box fabrication we process:

Steel – this material offers robust strength, ductility, and fracture resistance. It has an improved strength and corrosion resistance.

Aluminum – A lightweight, non-corrosive, durable, and easily machined and cast material.

Magnesium – a very strong material, shiny, and lightweight. It is easy to machine and offers excellent resistance to corrosion. It has low density perfect for boxes that require stiffness.

Bronze – high ductile metal, low metal-to-metal friction, high resistance to corrosion with a low melting point feature

Copper – outstanding heat and electrical conductor. It is ductile and malleable material.

Excellent has a wide range of sheet metal box fabrication capabilities. As a reputable manufacturer, we have passed ISO certifications, follow strict quality control and inspection.Highly skilled engineers and designers support us. We are well-experienced in this industry for more than 10 years. Our team can help you from all stages of the assembly process from the design and fabrication of your final products.

Excellent is the top-notch sheet metal box fabrication service provider in China with 1000+ satisfied clients worldwide. We offer a custom design option for your needs.